MANUFACTURING PROCESS CONTROL

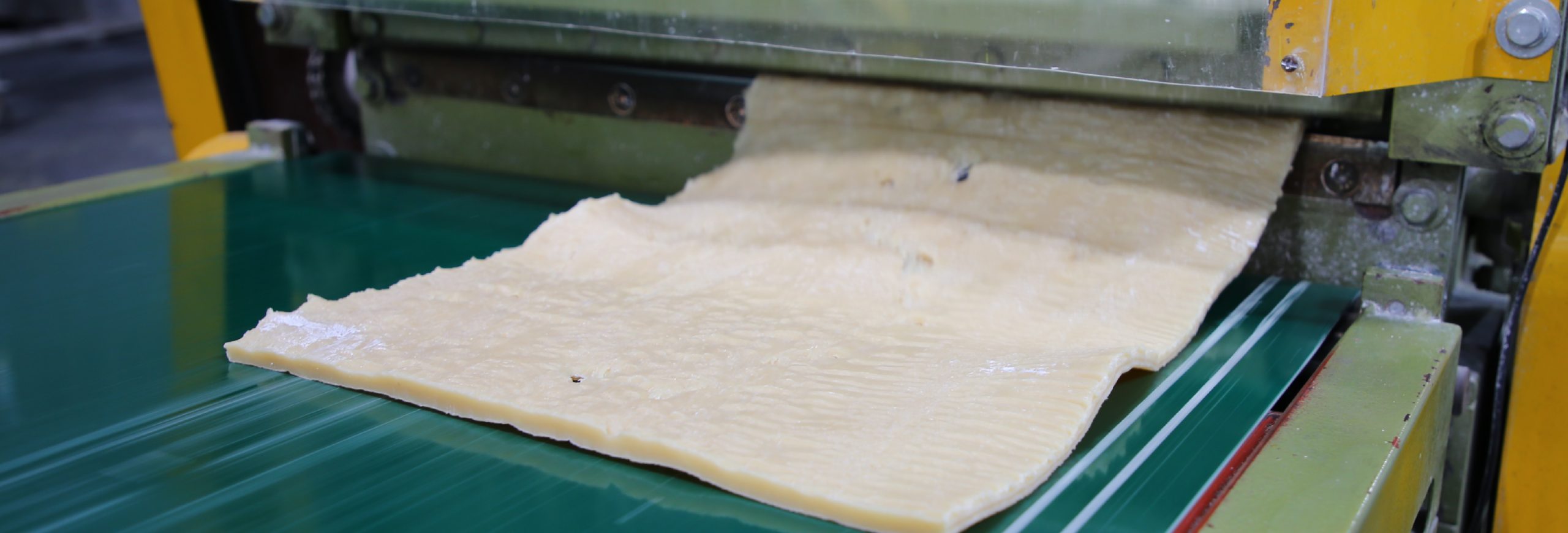

Computerized Control System (EPR) : We use the manufacturing process control system with ERP program that can control

work internal link to quality control of rubber compound efficiently

Computerized Control System (EPR) : We use the manufacturing process control system with ERP program that can control

work internal link to quality control of rubber compound efficiently

We use cookies to improve performance. and good experience using your website You can study the details at Privacy Policy เราใช้คุกกี้เพื่อพัฒนาประสิทธิภาพ และประสบการณ์ที่ดีในการใช้เว็บไซต์ของคุณ คุณสามารถศึกษารายละเอียดได้ที่นโยบายความเป็นส่วนตัว We use cookies to improve performance. and good experience using your website You can study the details at Privacy Policy We use cookies to improve performance. and good experience using your website You can study the details at Privacy Policy